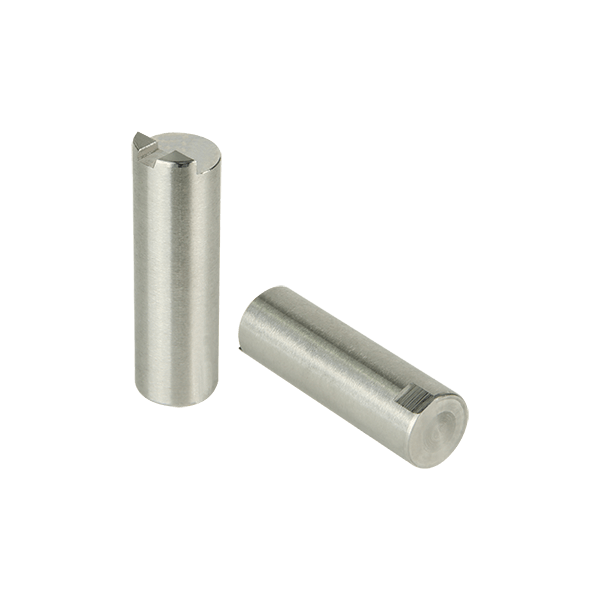

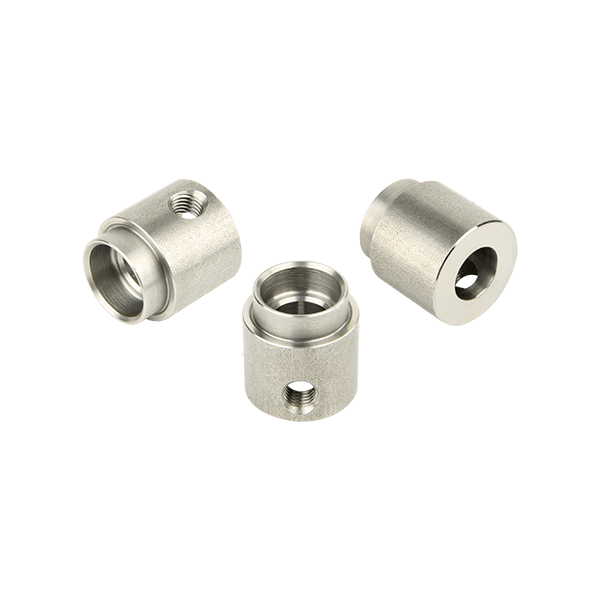

Product Image

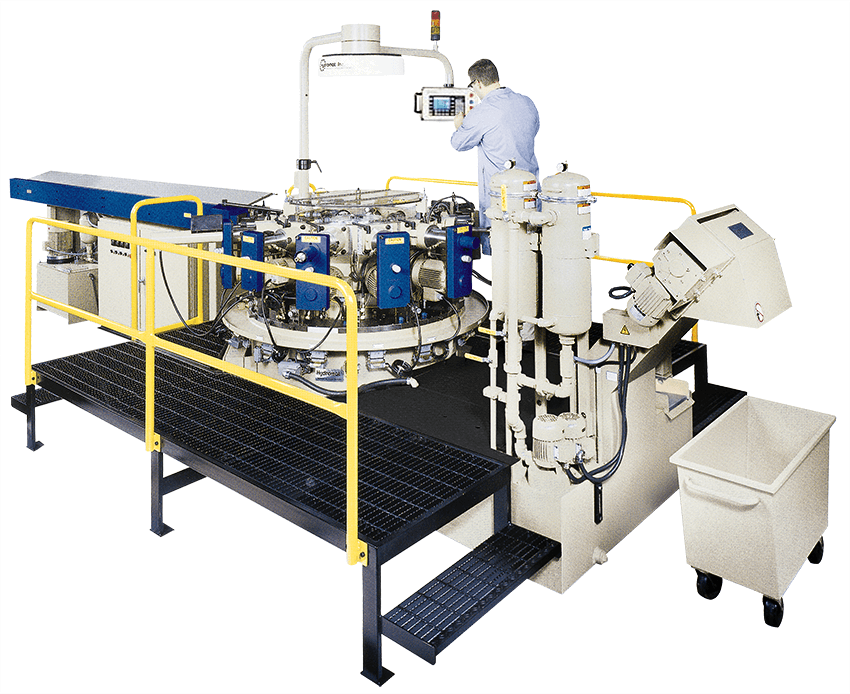

The HW 25-12 rotary transfer machine is a modular system consisting of up to 12 horizontal and 6 vertical spindles until rigidly mounted around a precision cast iron ring. This arrangement has the capability of providing tremendous versatility and flexibility in a turn-key machining system.

With 1" capacity, the HW 25-12 machine is ideally suited to produce parts from bar stock or blanks up to 4" in length.

Consistent, high productivity and precise machining, combined with the elimination of costly secondary operations make the HW 25-12 machine and outstanding solution for cost effective manufacturing.

Features

- Up to 12 horizontal & 6 machining stations

- Eliminates secondary operations

- Extreme accuracy and reliability of a Hirth ring

- Several different unit sizes available

- Coolant chiller optional

- Multiple loading and chip system options

Hydromat Advantages Over Conventional Machining

- Eliminates secondary operations

- Extremely short remnants and thin cutoff for significant material saving

- Reduces work in progress

- Increased productivity due to bar change and quick changeover capabilities

- Non-rotating bar stock provides quiet vibration free operation

- Modular toolspindles with quick-change presettable heads for easy changeovers

- Easily adapted for vertical machining requirements - up to 6 stations

- Easily accessible operating controls and machine adjustments

- Coolant and chips contained in the tooling area away from motors and controls

- Precision table indexing and repeatability ensures accuracy with SPC to 2.0 CpK

- Inverting unit repositions part for complete end to end machining

Technical Specification Table

| Max Stock Size | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Rnd | Hex | Sq | Length | Hor. Station | Vert. Station | Index Time | Weight LBS | Machine Power | Size Unit Options |

| 1" | 7/8" | 3/4" | 4" | 12 | 6 | 0.500 sec | 10,000 | 30HP (Avg) | 20/80 26/80 35/60 36/100 |

Saint Louis, Missouri

Saint Louis, Missouri