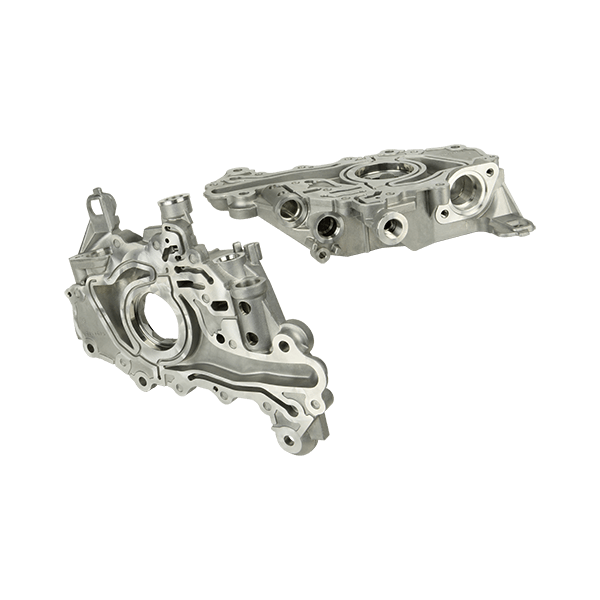

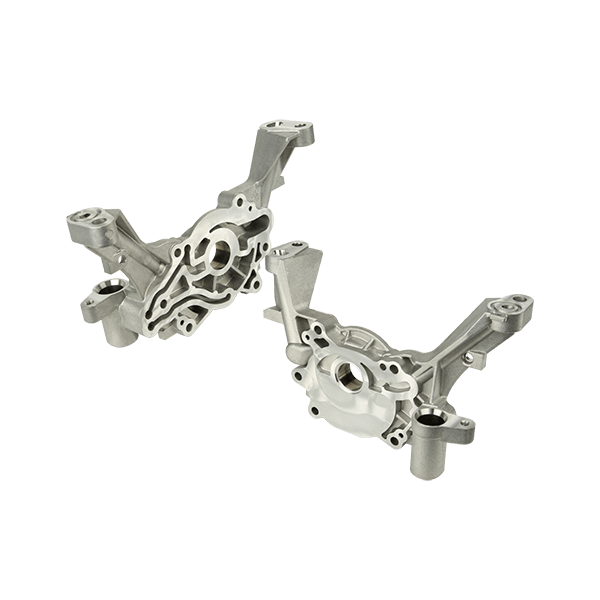

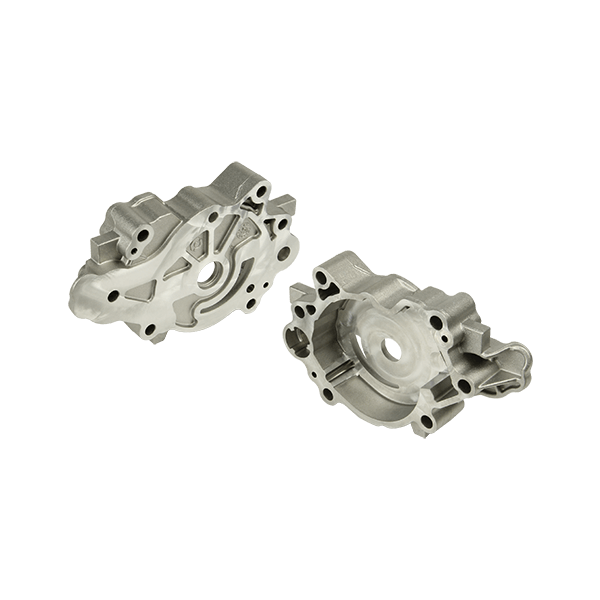

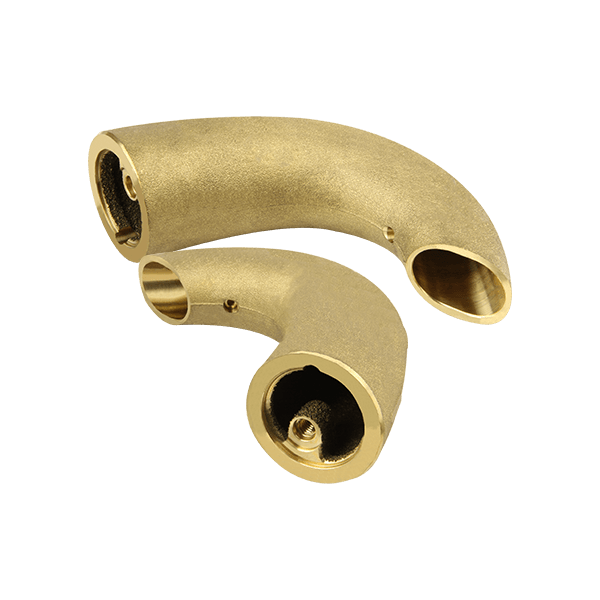

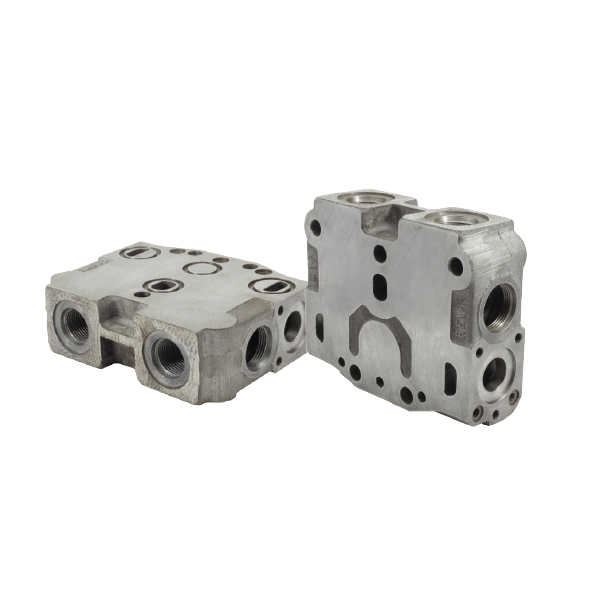

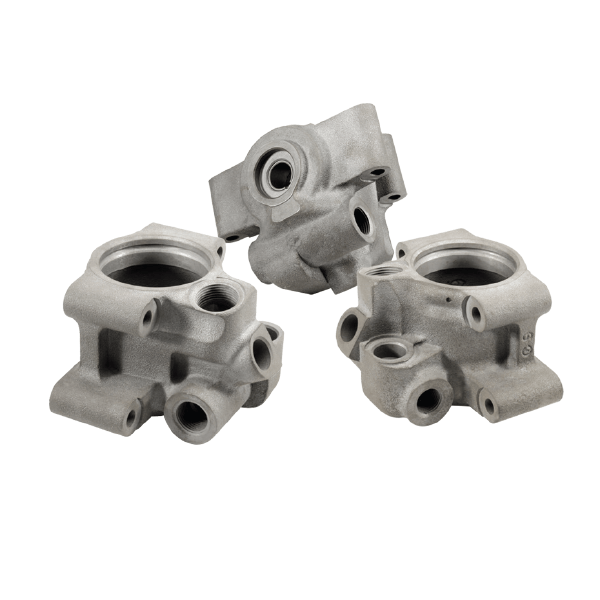

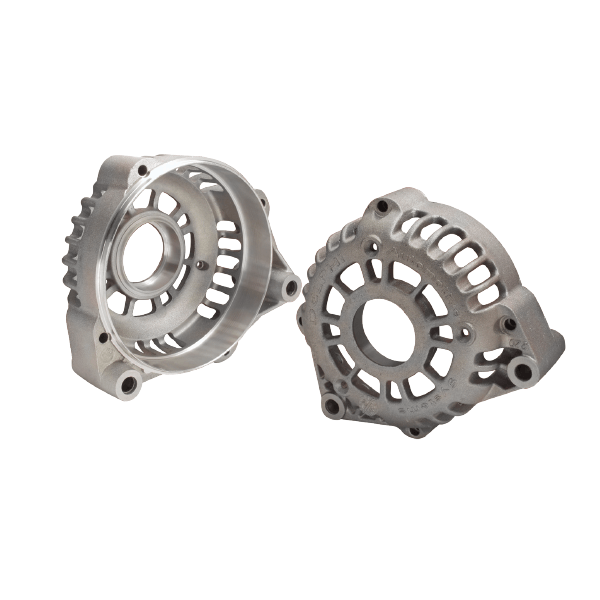

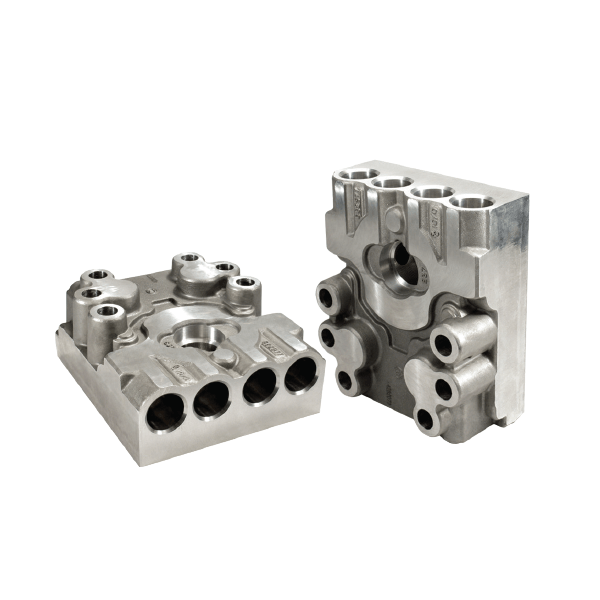

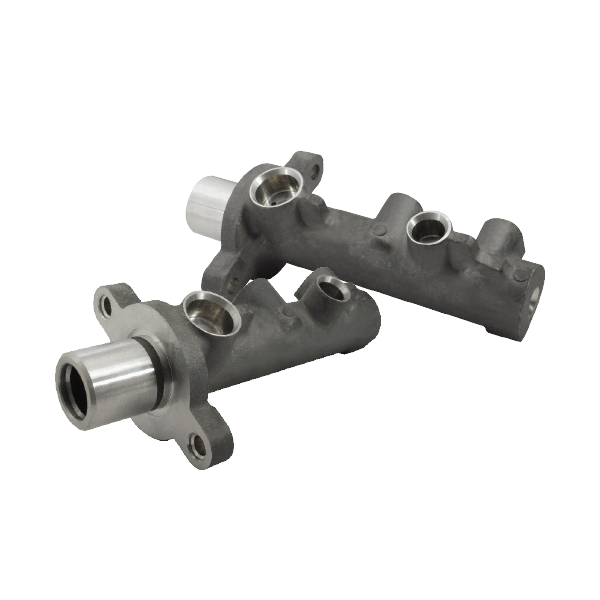

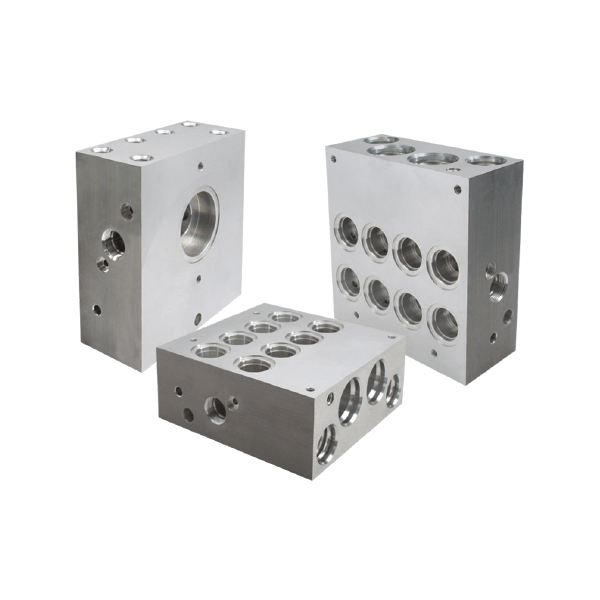

Product Image

Up To Eight Tools In The Cut At Once

The ICON part sizes range from a 2" cube to an 8" cube and can put up to eight tools in the cut at once with up to 8 machining units, four horizontal and four vertical units, each with a 10-tool changer fully equipped for your specific applications. Four cutting stations, each with integrated pallet changers produce 5 sided machining with 4 axis interpolation.

A Fanuc CNC controller has been incorporated as standard equipment on all ICON 6-250 machining centers.

These benefits coupled with the ICON’s flexibility creates a highly innovative solution to produce parts complete, with fast cycle times and a superior surface finish.

The Ultimate in Productivity & Flexibility

The unique design of the ICON 6-250 combines flexible machining center principles with Hydromat's rotary transfer production philosophy while incorporating engineering excellence with the finest materials and components.

Features

ICON Advantages

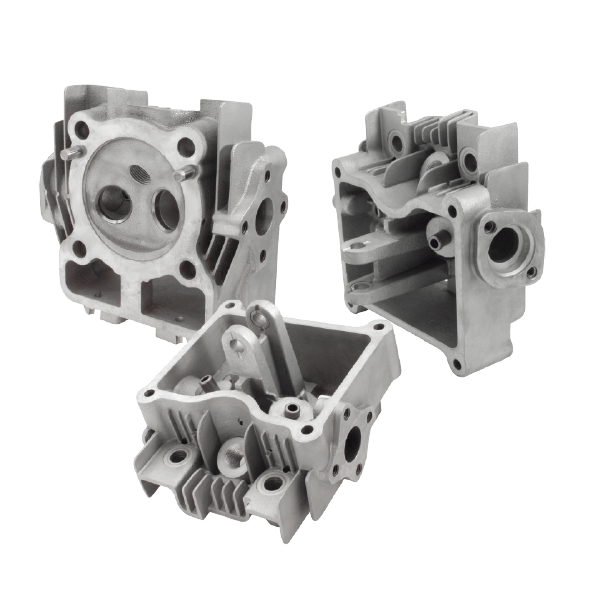

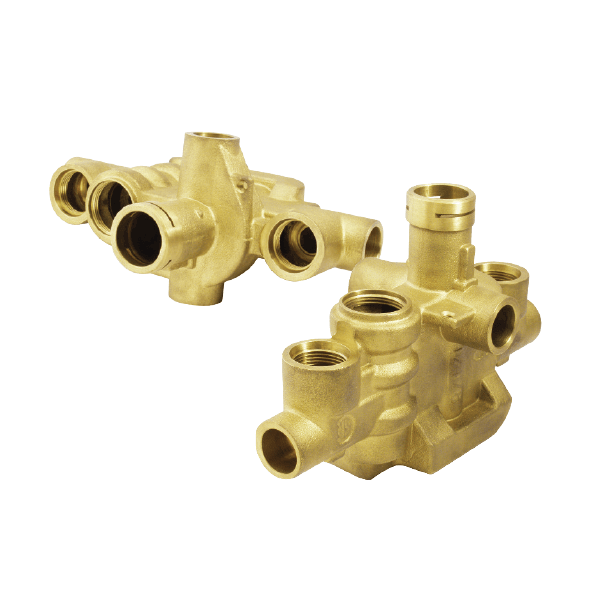

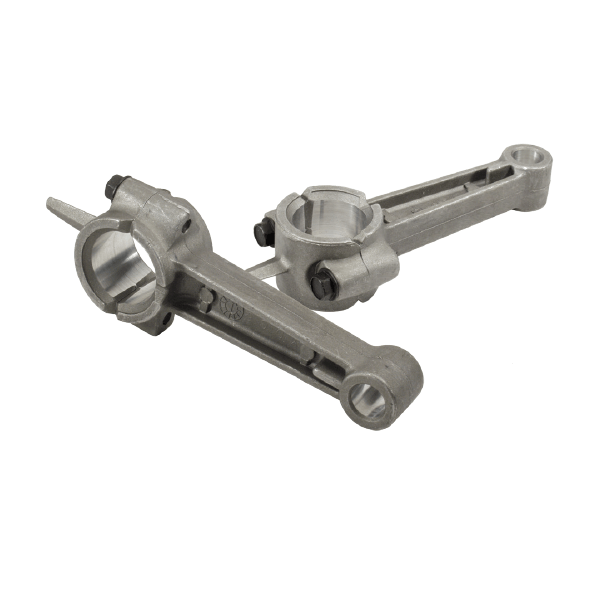

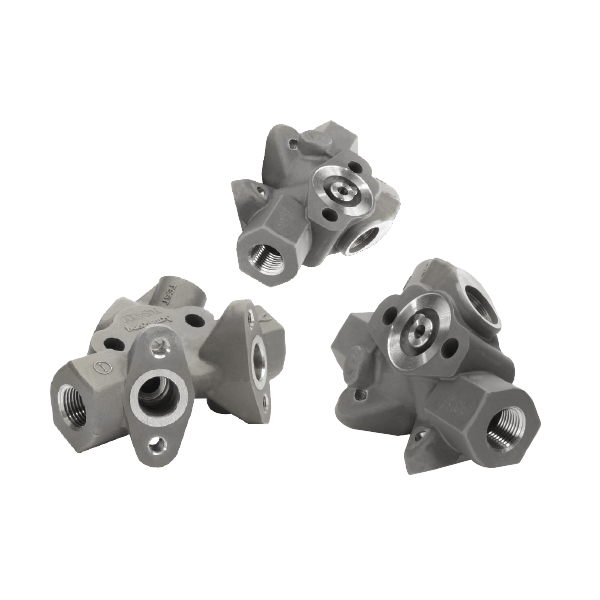

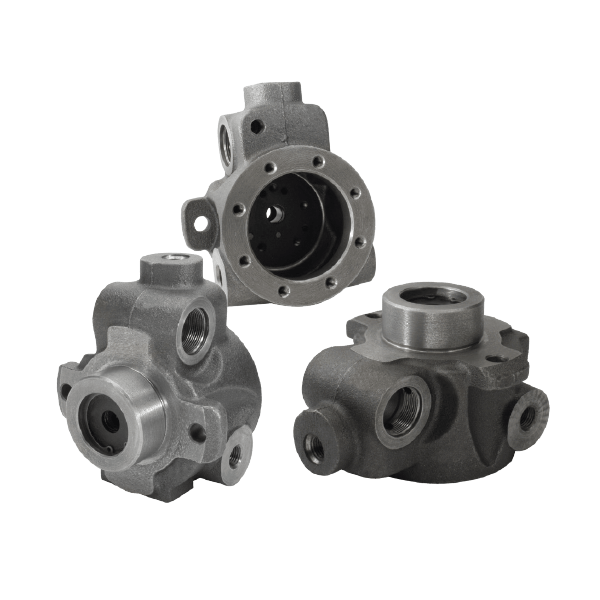

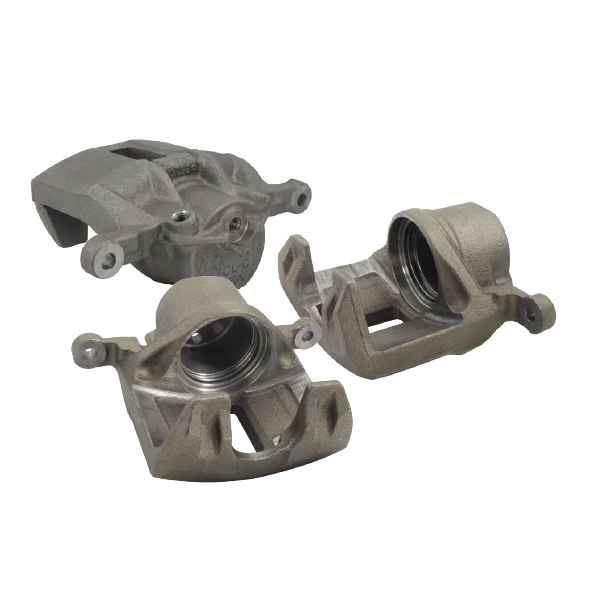

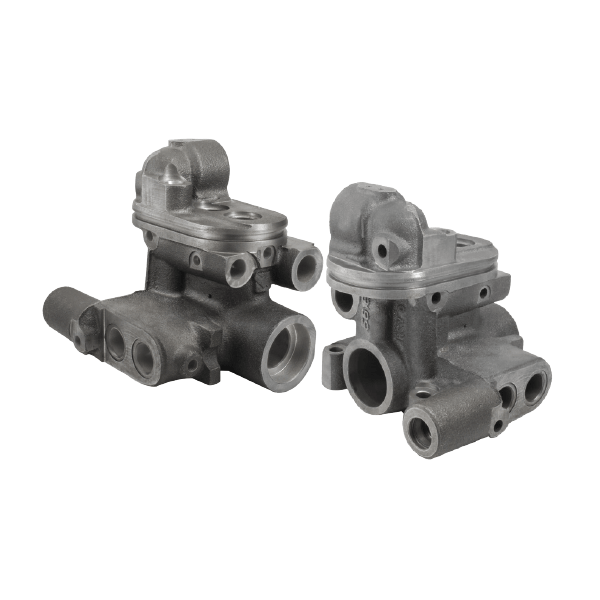

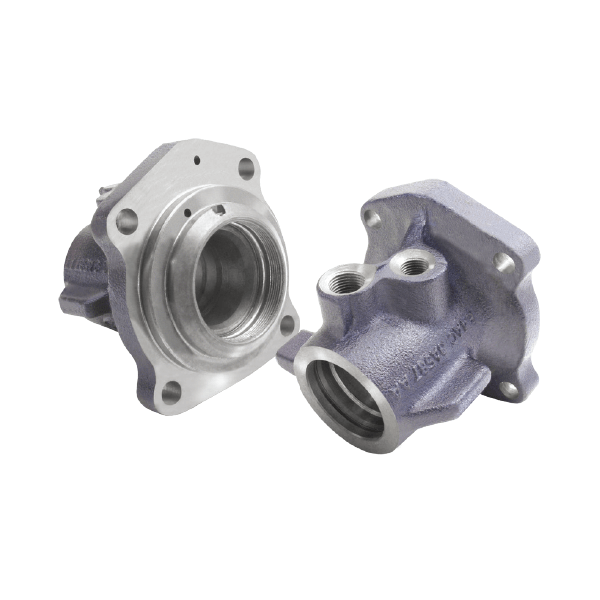

The ICON 6-250 offers an increase in speed and accuracy over other FMS type machining configurations. The ICON excels in production runs of near-net shapes, castings, and complex parts cut from billets.

Productivity has always been at the core of Hydromat's philosophy. The ICON's features combined with it's flexibility creates a highly innovative solution to produce parts complete, with fast cycle times and a superior surface finish. ICON project engineers work hand-in-hand with customers to develop a unique, tailored manufacturing process solution. An engineering committee comprised of a wide array of manufacturing disciplines, monitors every phase of each project. SPC values are carefully weighed during project evaluations.

What Makes the ICON 6-250 A Unique Productivity Center?

- Highly productive and flexible machining center for part sizes from a 2" cube to an 8" cube

- 8 Machining units with tool changers, fully equipped for specific applications

- 6 stations with integrated pallet changers

- 5 sided machining with 4 axis interpolation

- Fanuc CNC controller as standard equipment

- Load station designed for manual or robotic production configurations

- Four horizontal machining units and four vertical machining units on all fully equipped ICON 6-250 Machining Centers

- Idle station for re-clamping or gauging processes

The ICON 6-250 comes standard with the Fanuc 30i CNC Control, and features with a the complete package with all control components. For ease of operation, two pendants are mounted at Stations 1 and 4. Each pendant features a Fanuc 300 Model A operator control that includes a 10.4" color touch screen. The ICON machining modules feature feed motion with Fanuc servo motors, Schneeberger linear guide rails for all axis and healthy ball screw assemblies built for exceptionally long service.

Technical Specification Table

| Index Drives | Pallet Changer | Tool Changer |

|---|---|---|

| Amount of Index drives: 4 positions Index speed: 1.8 seconds for 180° Index accuracy: +/- 4 sec. Integrated control pivot includes: 3 hydraulic clamp circuits, 1 hydraulic return, and 1 air burst |

Integrated electromechanical system, torque motor Amount of pallets: 6 Pallet changing time: 4.5 seconds Max. Pallet Load: 200 lbs each (Higher Pallet Loads Optional) |

Tool head receiver: HSK A63 12 tool positions per changer Chip to chip: 3.5 seconds Maximum tool length: 250mm (10”) Maximum diameter: 125 mm (5”) Maximum tool weight: 15 lbs |

| Coolant System | Loading Station | |

| Coolant tank: 1200 gallons Filtration system with vacuum, self cleaning Low pressure coolant: 2 bar Medium pressure coolant: 30 bar High pressure coolant: 80 bar (Optional) High pressure coolant: 120 bar (Optional) |

Manual, Semi-Automatic or Robotic |

| 3-Axis Machining Module | |

|---|---|

| Integrated Spindle Motors (Standard): |

Water Cooled |

| Spindle Performance: | Spindle RPM: 12,000 max Acceleration: 1.0 sec. to 12,000 RPM Spindle Bearing Size: 70mm |

| Optional Spindle RPM: | 8,000 RPM Max: 36 kW 24,000 RPM Max: 48 kW |

| Pre-Tensioned Ball Screws: | X Axis: 40mm X 10mm Pitch Double Lead Y Axis: 50mm X 20mm Pitch Z Axis: 40mm X 10mm Pitch Double Lead |

| Machining Stroke & Force: | X Axis: 300mm @ 22 Nm Y Axis: 300mm @ 30 Nm Z Axis: 375mm @ 22 Nm |

| Size & Weight: | X Slide: 630mm X 840mm Y Slide: 570mm X 540mm Z Slide: 250mm X 250mm Weight: 1200 kg |

Saint Louis, Missouri

Saint Louis, Missouri