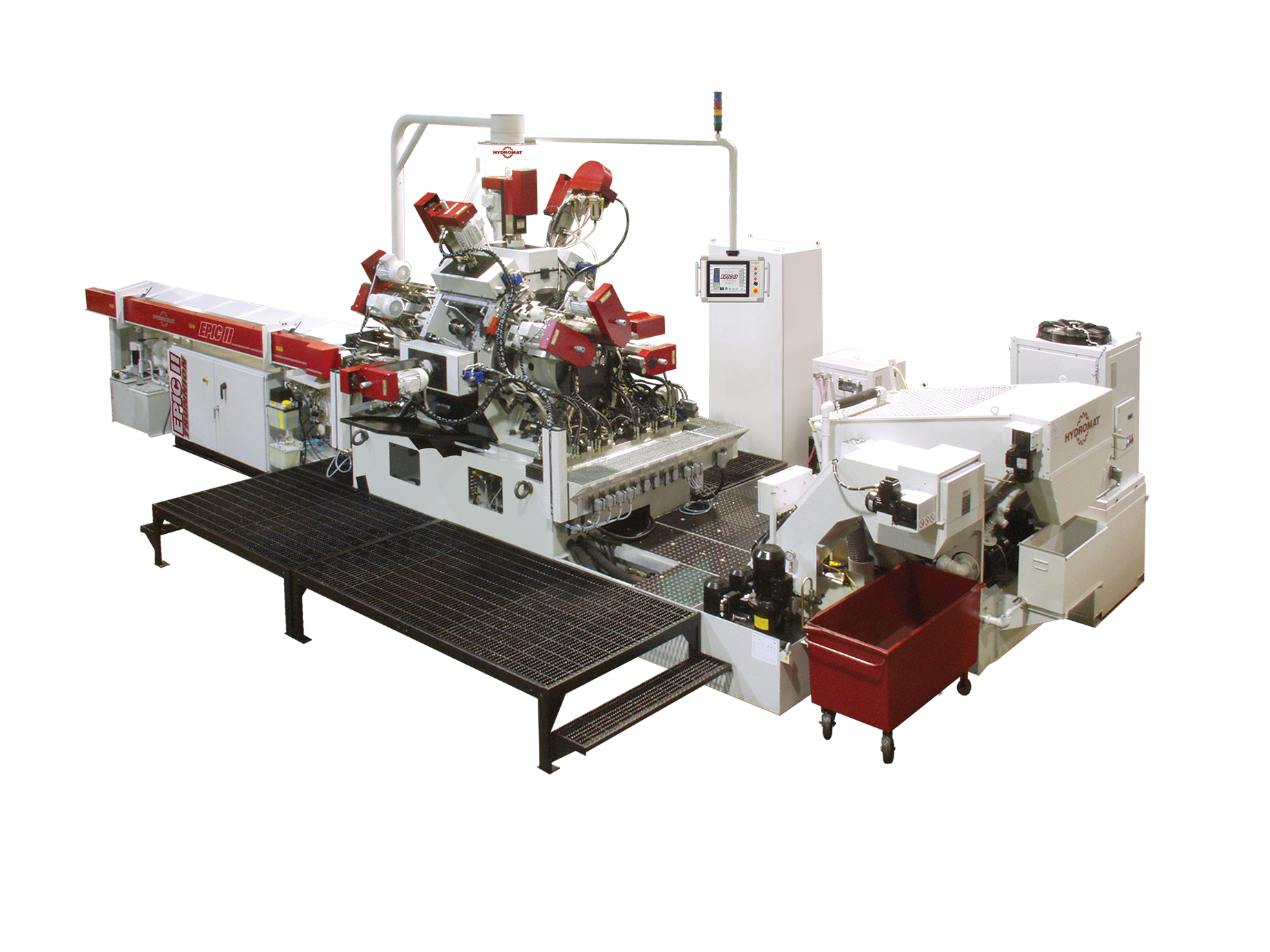

Product Image

The EPIC II Trunnion rotary transfer machines come in two models; the V8 and V12. These models are equipped with the EPIC II CNC control featuring plug-and-play toolspindles for greater flexibility.These modular machines provide tremendous versatility and flexibility in a turnkey machining system.

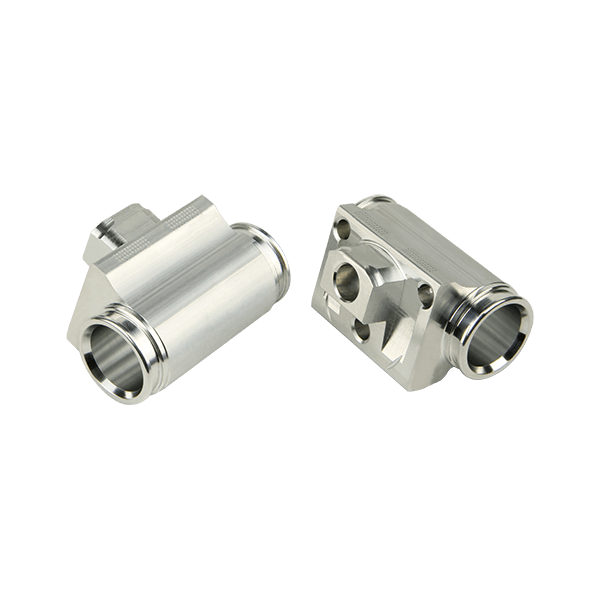

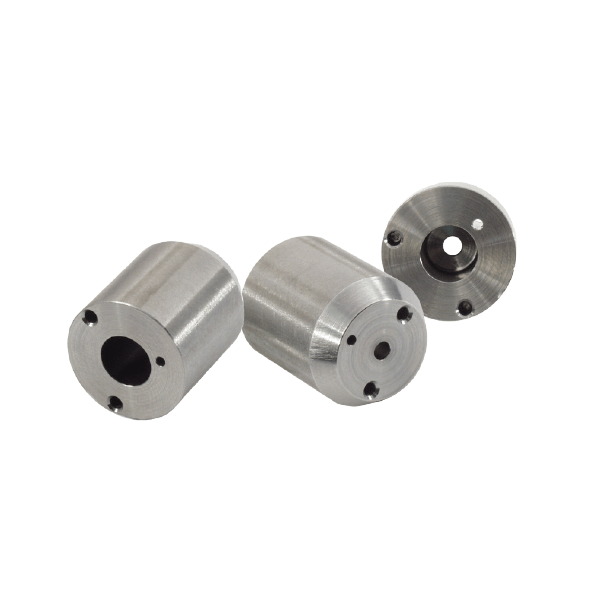

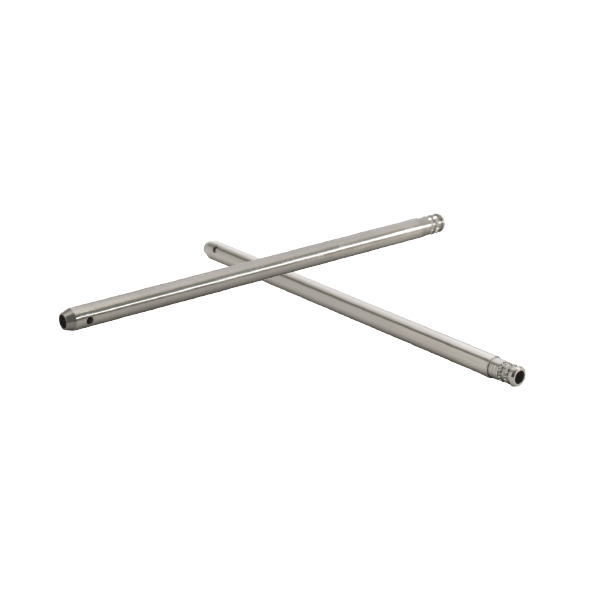

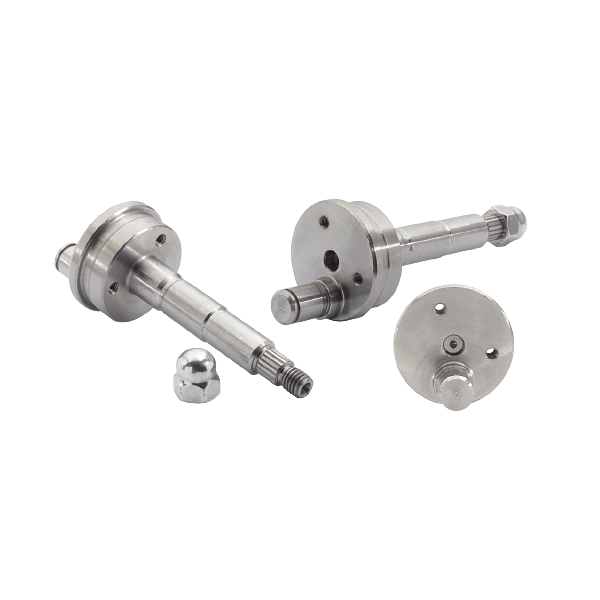

Hydromat Trunnion machines are well suited for the manufacturing of small casting applications, irregularly-extruded bar stock parts and shafts from 1/2” to 12” in length. The Trunnion machines are equipped with 8 (V8 machine) or 12 (V12 machine) chucks. These hydraulically actuated, self-centering chuck jaws keep the workpiece stationary while the table indexes to each machining position.

Consistent, high productivity and precise machining, combined with the elimination of costly secondary operations make the Trunnion machines an outstanding solution for cost effective manufacturing.

Features

- Up to 18 horizontal & 9 vertical machining stations

- Small casting applications, irregularly extruded bar stock parts, and shafts from 1/2” to 12” in length.

- Several different unit sizes available

- Multiple Loading and Chip Systems options

- Coolant fed or Flange Quill operations

- Every machine sold is individually engineered for optimal cycle time

- Full CNC programming capabilities

- Supports lean manufacturing principals

- Integrated modem connections provide fast problem solving

- Enhanced Operation, Trouble Shooting, and PM Intervals

- Standard CNC Controls for Improved Part Set-Up, Change-Overs, and Process-Tooling Development

- Integrated Tool Monitoring

Hydromat Advantages Over Conventional Machining

- Eliminates secondary operations

- Extremely short remnants and thin cutoff for significant material saving

- Reduces work in progress

- Increased productivity due to bar change and quick changeover capabilities

- Non-rotating bar stock provides quiet vibration free operation

- Modular tool spindles with quick-change presettable heads for easy changeovers

- Easily adapted for vertical machining requirements - up to 6 stations

- Easily accessible operating controls and machine adjustments

- Coolant and chips contained in the tooling area away from motors and controls

- Precision table indexing and repeatability ensures accuracy with SPC to 2.0 CpK

- Inverting unit repositions part for complete end to end machining

EPIC II Control Benefits

- No PMAC EPIC Boxes

- Bosch CNC/PLC Common Control

- Direct Access for Valves, Programming, & Feedback

- Standardized Common Servo Valve

- Reduced Wiring and Machine Plugs

- Efficient Architecture with Reduced Failure Points

Technical Specification Table

| Max Stock Size | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Rnd | Hex | Sq | Length | Hor. Station | Vert. Station | Index Time | Weight LBS | Machine Power | Unit Size Options |

| 1 3/4" | 1 1/2" | 1 1/4" | .5" - 12" | up to 18 | up to 8 | .9 sec | 16,500 | 60HP (Avg) | EPIC 26/80 EPIC 36/100 EPIC 46/120 (V8 Only) EPIC 50/100 |

Saint Louis, Missouri

Saint Louis, Missouri