Product Image

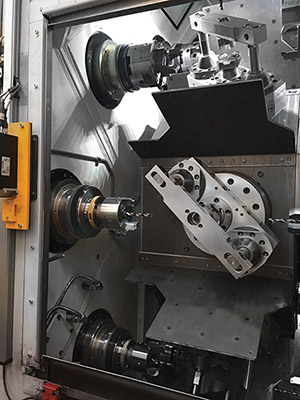

The LSA 8-200 model has seven machining stations that feature 2-jaw chucks or custom fixtures for cast blanks. It also has one dedicated loading station and one station for gauging, inverting, or other special processes. It features four to six stations with six, eight or a maximum of ten horizontal units and two or three radial units. These can swivel and be adjusted, and thus are able to adapt to changing workpiece shapes.

The LSA 8-200 model has seven machining stations that feature 2-jaw chucks or custom fixtures for cast blanks. It also has one dedicated loading station and one station for gauging, inverting, or other special processes. It features four to six stations with six, eight or a maximum of ten horizontal units and two or three radial units. These can swivel and be adjusted, and thus are able to adapt to changing workpiece shapes.

The unique design of the LSA 8-200 is anchored by a robust frame weldment that is precision machined by the finest German craftsmen. It incorporates engineering and design excellence with the finest materials and components used in its creation. The results: a machining center of robust construction and exceptional accuracy.

The work envelope is a large 150mm x 100mm x 125mm. Part loading can be Flexible Manual or Robotic at the one dedicated loading station. One station is dedicated for gauging and special devices, and there are seven cutting stations featuring self centering two-jaw chucks, or the use of custom designed fixtures for complex castings.

The LSA design is a multi-way production cell with horizontal turret axis can be used to complement other rotary transfer automatic systems.

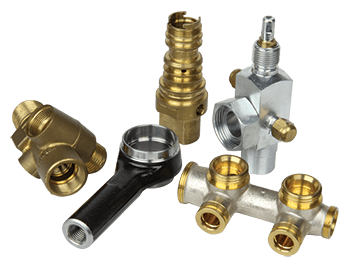

The machine application is based on the clamping position of the workpiece, flexibility required for the machine, access for setting up and the number of radial units.

The machine application is based on the clamping position of the workpiece, flexibility required for the machine, access for setting up and the number of radial units.

The machine base exhibits high static and dynamic rigidity and allows excellent access to the workspace, as well as for the removal of chips.

The indexing unit is cycled between the machining stations with extreme accuracy and repeatability during the rotary transfer process. It can be customized to accept an infinite number of workpiece clamping fixtures. It is also possible for two fixtures to be located next to each other. In this set-up, machining of two workpieces can be completed in one cycle, or one workpiece can be in the first or second clamping (multi-sided machining; A/B load).

Clamping of the workpiece is usually hydraulic, e.g. self-centering clamping in two or three jaw chucks, clamping fixtures, collet chucks, swivel-mounted clamping jaws or clamping arbors.

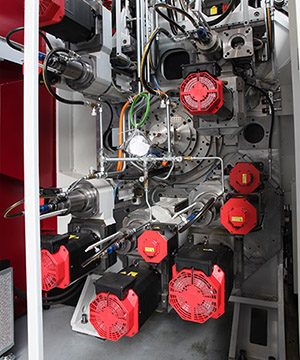

For the LSA three spindle sleeve sizes are available. There are hydraulic or mechanical machining units in various sizes that enable light or heavy material removal, and also the use of multi-spindle heads.

For the LSA three spindle sleeve sizes are available. There are hydraulic or mechanical machining units in various sizes that enable light or heavy material removal, and also the use of multi-spindle heads.

For precise and reliable long-term usage, our hydraulic linear drives (HLD) are also provided as an option. With their user-friendly high performance technology, they are an optimum drive solution.

The feed rate is 0 to 20,000 mm/min with a rapid feed rate of 20,000 mm/min. The LSA modules feature size 35 preloaded linear monorail guides. This powerful system yields a maximum feed force of 7000N, yet holds an impressive position accuracy of TP 0.007mm.

The 3-axis modules feature 20m/mm single lead ball screw assemblies, with the Z-Axis having a 180mm stroke while the X-Axis and Z-Axis both featuring a 60mm stroke each.

For increased production safety additional equipment can be introduced such as tool breakage or wear controls, tool life monitors, workpiece measurements, defect diagnostics systems, and more.

Special equipment, such as the automatic feed of assembly parts, loading and unloading by means of robots, or complete interlinked systems, make the LSA a high productivity machine.

Saint Louis, Missouri

Saint Louis, Missouri