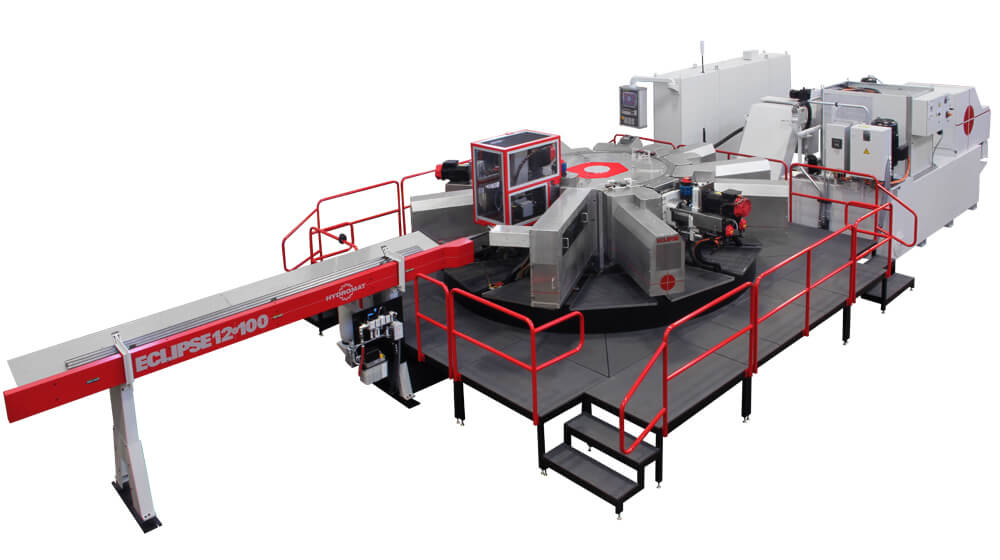

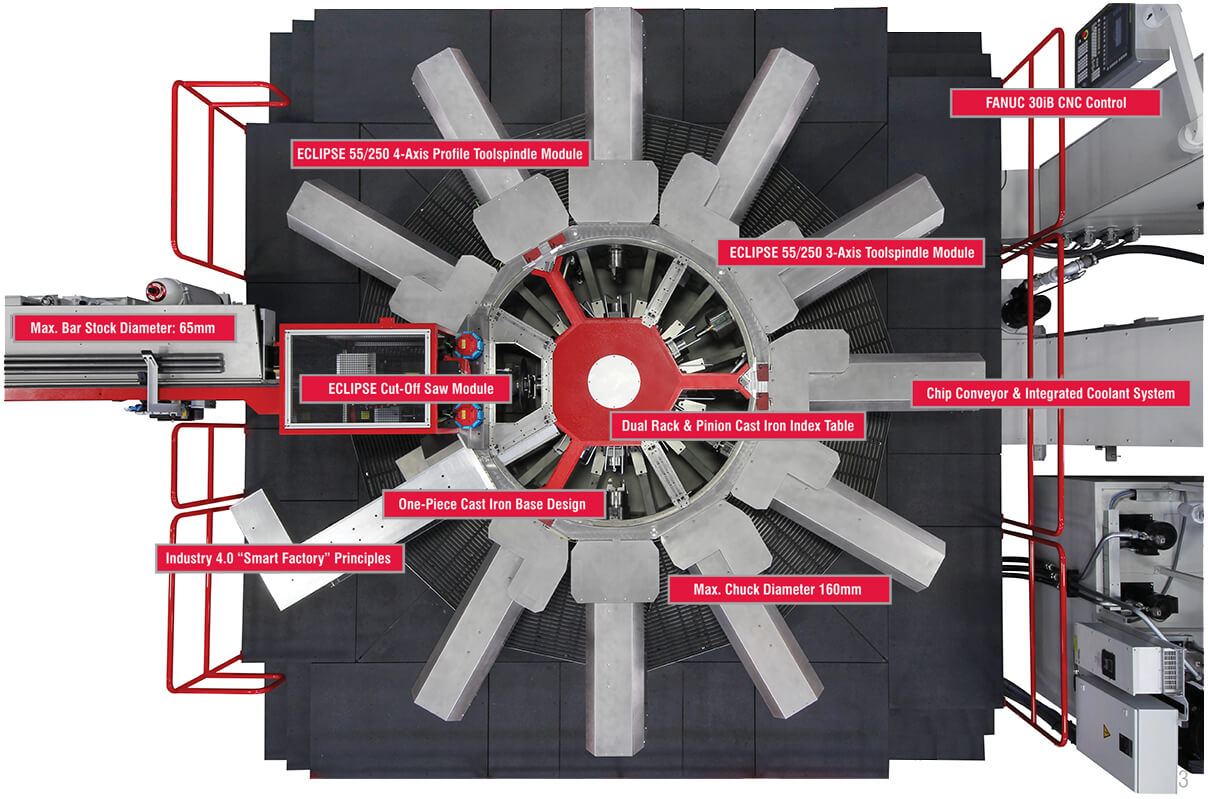

Product Image

The new Eclipse 12-100 is a ground-up redesign of the famous Hydromat multi-spindle rotary transfer machine concept with all new components. It features a heavy duty cast iron machine frame that is 2m in diameter, nearly twice as large as the traditional 12 station Hydromat machine.

The new Eclipse 12-100 is a ground-up redesign of the famous Hydromat multi-spindle rotary transfer machine concept with all new components. It features a heavy duty cast iron machine frame that is 2m in diameter, nearly twice as large as the traditional 12 station Hydromat machine.

This machine platform offers multiple tool spindles in a single footprint integrated with one chip management & coolant system.

Robot load/unload with auto inverting offers six-sided machining capability on both bar and blank loading applications.

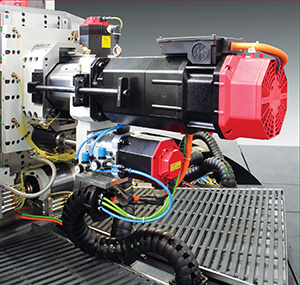

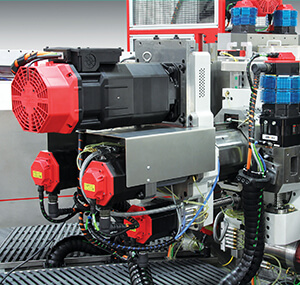

Each of the 12 tool spindle modules features 3-axis or 4-axis capability with all electric servo spindles and high-tech components such as heavy-duty linear guideways for high accuracy, and large bearing diameters for extra stability, that yield smoother cutting at higher speeds. The Eclipse CNC control has fixture mapping capability for exceptional station to station accuracy. Designed to be exceptionally rigid, these modules were designed with hefty castings for superior vibration dampening properties and maximum precision.

The Eclipse offers a high degree of machining flexibility derived through engineering expertise coupled with a visionary concept, the type of creative thinking that has produced this superior Rotary Machining Center for small to large batch production.

Features

- Heavy duty cast iron base with 12 horizontal positions and 100mm (Chucks) work-holding capacity

- Up to five vertical tool spindle units available as options

- FANUC 30iB CNC control and touch screen operator pendent interface

- Index Table equipped with Hirth Ring coupling providing indexing accuracy and repeatability

- Table index time: 0.9 seconds

- Quick change Hainbuch collet and chuck table clamping systems

- Vertical Sliding Cut-Off Saw module

- Standard all electric 3 and 4-axis tool spindle modules

This multi-station transfer technology enables load and unload processes on station one, and simultaneous machining on the other 11 stations; making the Eclipse 12-100 ideal for medium to high production of complex work pieces requiring multiple operations, complex cuts, and where tight tolerances are critical.

The Eclipse was developed with the proper principles to support companies who are identifying and implementing Industry 4.0 design scenarios: Interoperability, Information Transparency, Technical Assistance, and Decentralized Decisions. The Eclipse 12-100 is ready for the Fourth Industrial Revolution.

ECLIPSE 12-100 Index Table

- Table index 0.9 seconds

- Hydraulic actuated rotation, lift and down function

- Servo hydraulic single or double index function

Horizontal Collet Platform

- 12 hydraulic actuated Hainbuch stationary Quick Change clamping devices with 65mm maximum clamping capacity and hexagon draw type clamping geometry

- Optional: HB45 Collet - Ø 40mm

Horizontal Chuck Platform

- 12 hydraulic actuated Hainbuch Quick Change two or three-jaw chuck system with 100mm maximum clamping capacity

Vertical Chuck Platform

The Eclipse Vertical Indexing Chuck machine utilizes hydraulically-actuated, self-centering two or three-jaw chucks or custom clamp fixtures to provide the highest accuracy and part clamping rigidity. This type of chuck indexing provides precise part positioning for complex multi-axis machining that requires one chucking to maintain overall part quality and statistical capability.

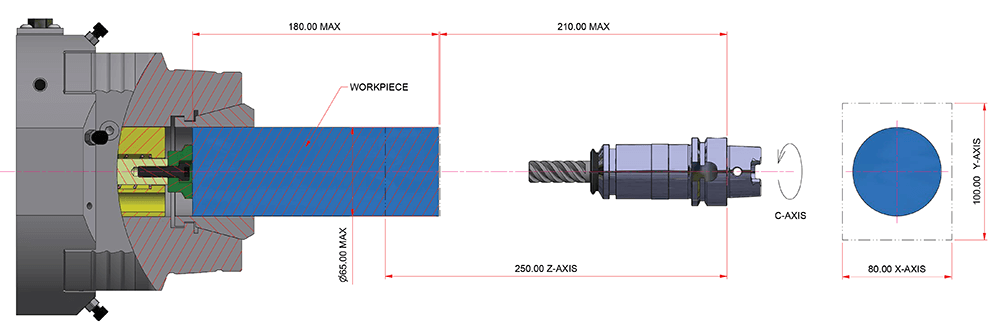

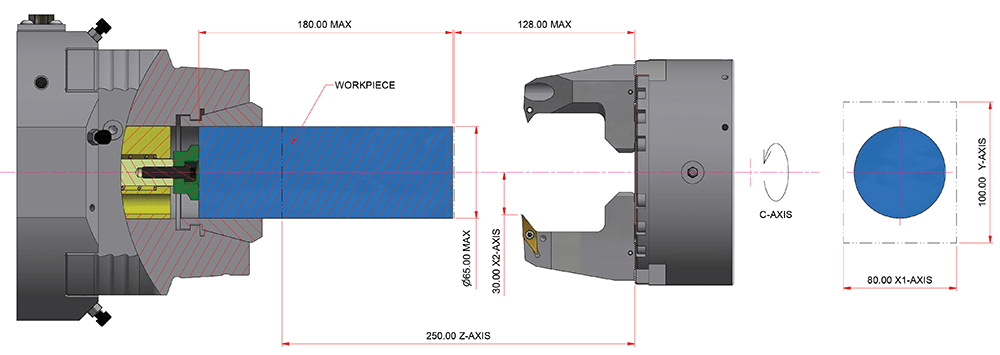

ECLIPSE 55/250 3-Axis Toolspindle Module

- Direct drive spindle motor with Ø 55mm front bearings and a 250mm Z-axis stroke

- 80mm X-axis and 100mm Y-axis CNC slide stroke

- FANUC 8,000 or 12,000 rpm servo motor

- HSK-C50 tool holder interface

- Optional coolant fed

ECLIPSE 55/250 4-Axis Profile Toolspindle Module

- Belt driven spindle with Ø 55mm front bearings and a 250mm Z-axis stroke

- 80mm X(1)-axis and 100mm Y-axis CNC slide stroke

- FANUC servo motor

- Flange spindle for mounting dynamic profile turning head with 30mm X(2)-axis stroke

- Ø 160mm dual or single slide 5,000 rpm profiling head

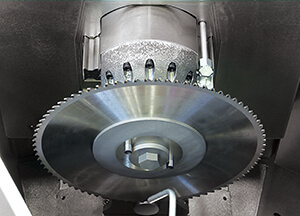

A Revolution In Cut-Off Technology

A revolutionary new cut-off saw was designed by Hydromat Inc. engineers, features bar and workpiece spacing prior to saw blade retraction after the cut. The saw’s two-speed drive motor with belt reduction yields a highly accurate cut.

ECLIPSE Cut-Off Saw Module

- Vertical slide motion to position saw blade above the bar stock and eliminate remnants damaging the blade

- 3-axis with direct drive dual winding servo spindle motor

- Bar and workpiece spacing during saw retract motion eliminates saw blade dragging on return motion

- Standard carbide tipped Ø 360mm saw blade

- 80mm Y-axis and 135mm Z-axis stroke

- 500 rpm base speed / Max. speed 6,000 rpm

- Standard Saw Blades with 360mm OD and 50mm ID

- 15 kW (20 HP) Fanuc Dual Winding Motor (Low winding with 500 rpm base speed / Max. speed 6,000 rpm)

- Saw Drive reduction ratio 4:1

- Dual winding motor coupled with the 4:1 reduction drive covers the speed range required to cut all basic materials

- Vertical Sliding Saw clears the bar stock on both sides of the saw blade prior to the blade retraction cycle

- High pressure coolant nozzles clear the saw gullets from chips during and after the cut

- No vibration dampening pads on the saw blade required due to the use of large blade clamping flanges

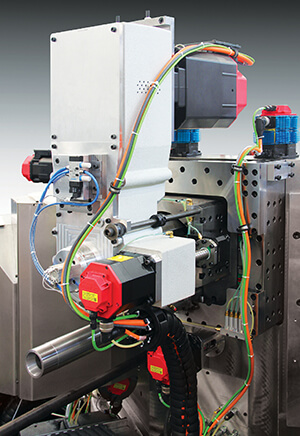

Bar Stock Loading System

Bar-fed versions of Eclipse machines will come equipped with a standard or bundle bar feeder, depending on the application and the production requirements.

Bar-fed versions of Eclipse machines will come equipped with a standard or bundle bar feeder, depending on the application and the production requirements.

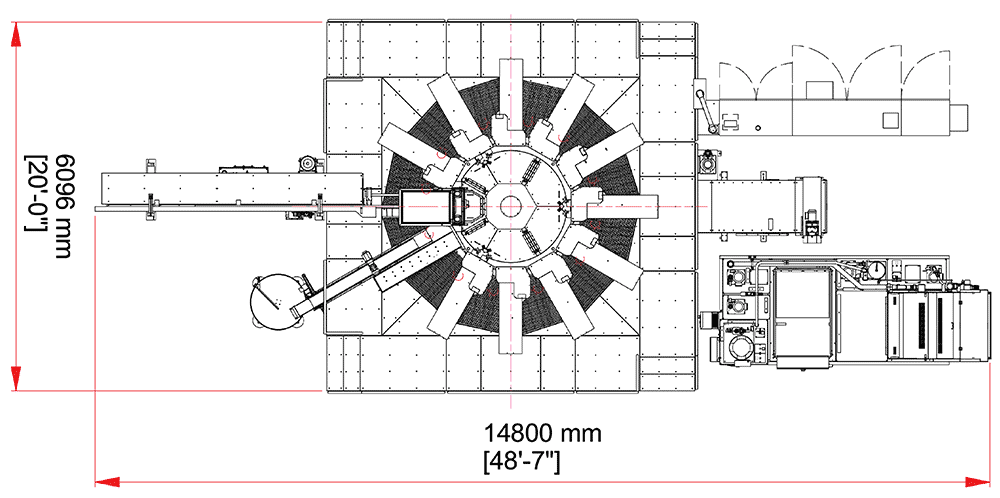

The bar-fed collet version of the Eclipse 12-100 has a maximum workpiece diameter of 65mm (2.5”) and features a maximum workpiece length of 180mm (7”) with 127mm (5”) of material outside the collet.

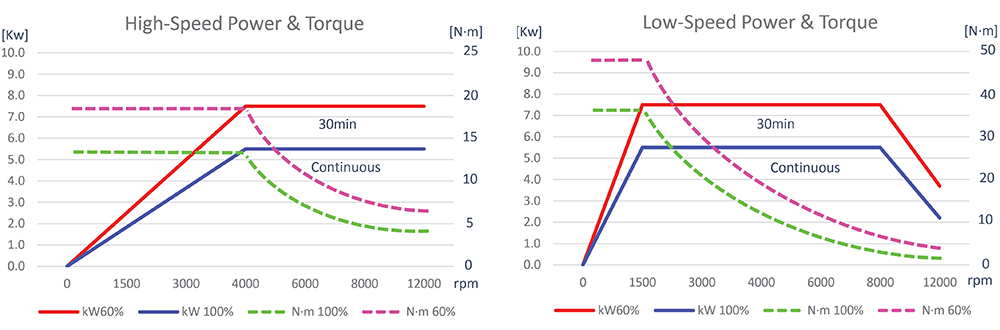

Fanuc 12,000 RPM Dual Winding Servo Motor POWER & TORQUE

Eclipse 12-100 (Overhead view)

Eclipse 12-100 (Overhead diagram)

Saint Louis, Missouri

Saint Louis, Missouri