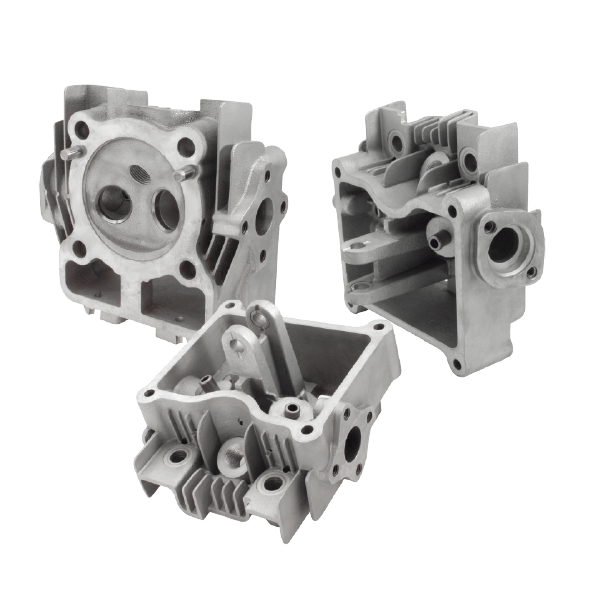

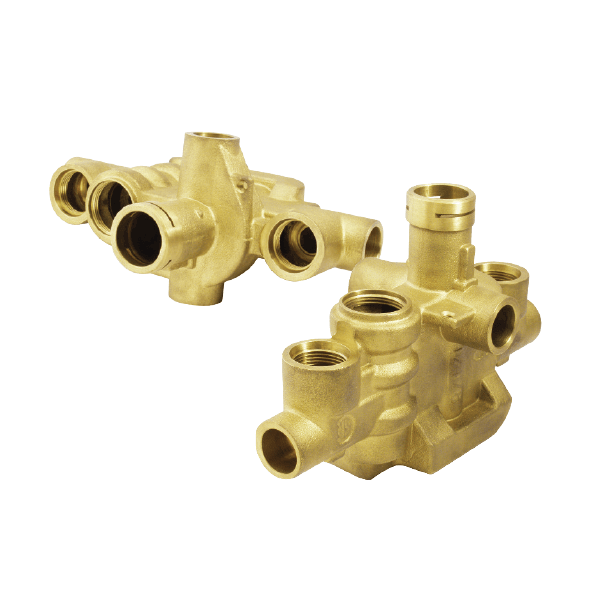

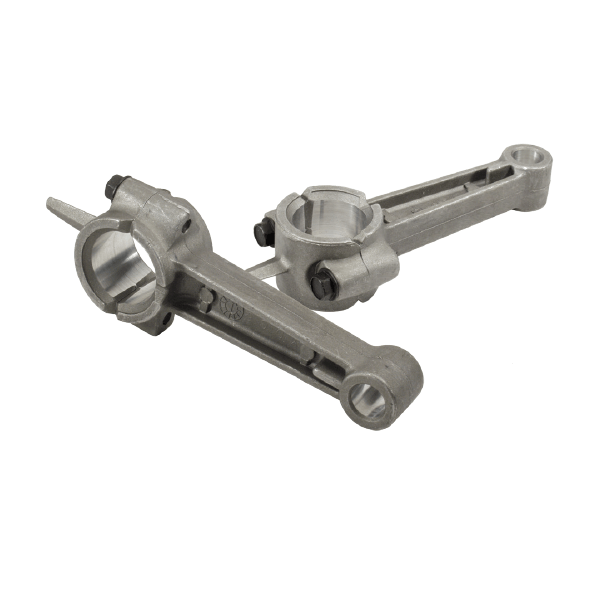

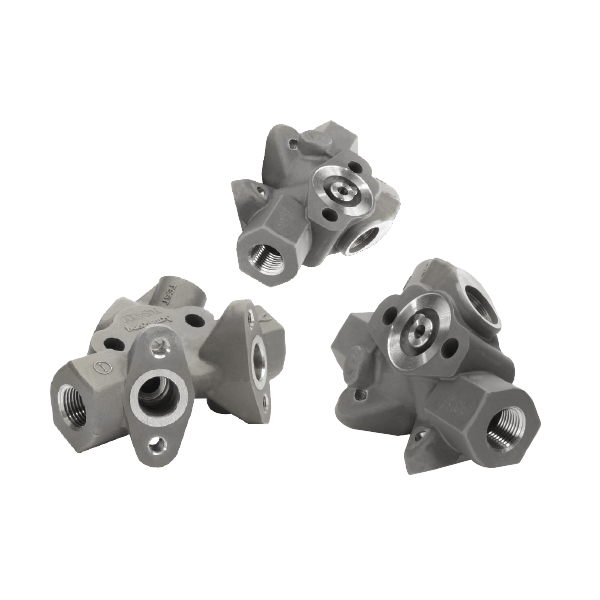

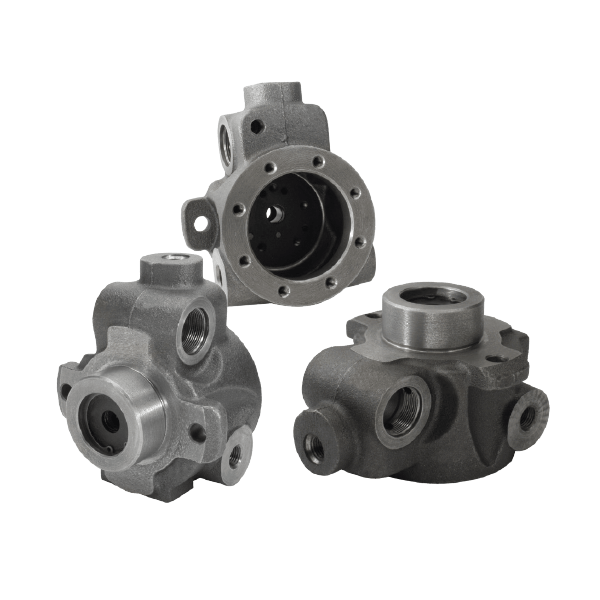

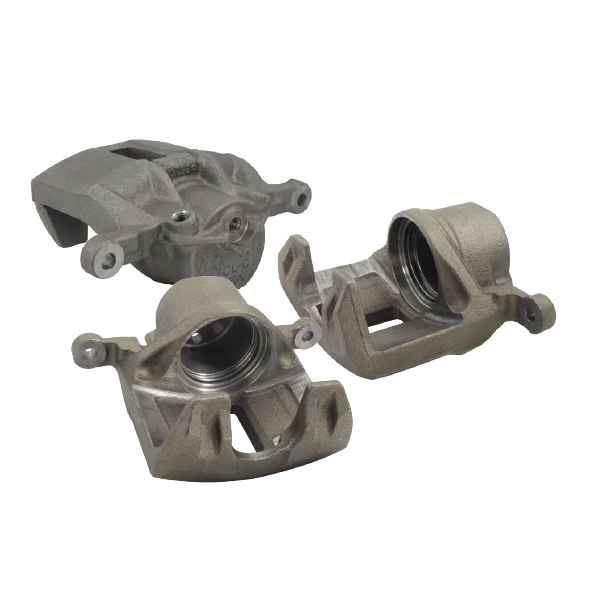

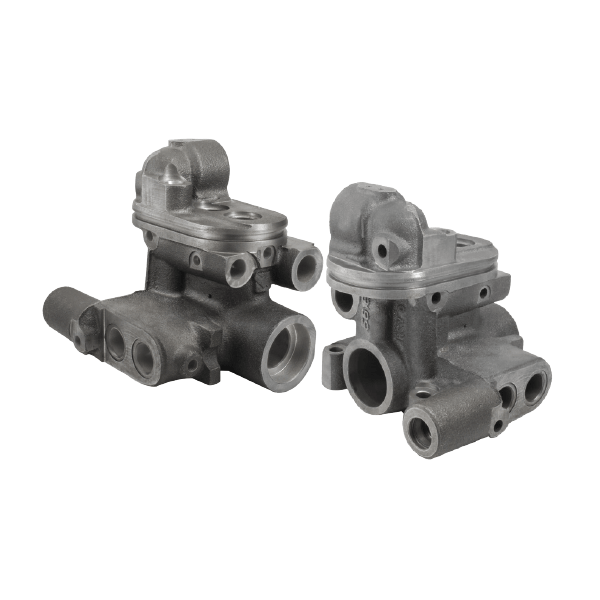

Product Image

Versatile System for Increased Production

The ICON 8-150 is designed with six machining stations and two dedicated loading/unloading stations, the ICON was developed around flexible machining principles. Equipped with a six position table, it shuttles pallets to four machining modules for fast, ultra-precision cutting.

These six cutting stations produce 5-sided machining with 4-axis interpolation; 6 sides if the idle station is used for work piece inversion.

These benefits coupled with the ICON’s flexibility creates a highly innovative solution to produce parts complete, with fast cycle times and a superior surface finish.

The Ultimate in Productivity & Flexibility

The unique design of the ICON 8-150 combines flexible machining center principles with Hydromat's rotary transfer production philosophy while incorporating engineering excellence with the finest materials and components. The results are a robust machining center with extreme versatility.

Technical Specification Table

| Index Drives | Pallet Changer | Tool Changer |

|---|---|---|

| Amount of Index drives: 6 positions Index speed: 0.9 seconds for 180° Rotation: 360.000x0.001° Maximum Turning Speed: 5,000rpm Maximum payload per pallet: 30 kg (66 lb) |

Direct Drive via Fanuc Torque Motor Amount of Pallets: 8 Single Index (8 x 45°) Double Index (3 x 90°) Table Index Time: 3.5 seconds |

Tool head receiver: HSK E40 12 tool positions Chip to chip: 3 - 4 seconds Maximum tool length: 140 mm (5.5 in) Maximum diameter: 45 mm (1.8 in) Maximum tool weight: 4 kg (8.8 lb) |

| Coolant System | Controls / Voltages | |

| 30μm high pressure Up to 80bar through spindle Self cleaning permanent media 75μm low pressure Paper or cartridge filter media |

Control: Fanuc 30i Drives: Fanuc 30i Main Voltage: 480V @ 60 Hz |

| Standard Machining Module | |

|---|---|

| Stroke: | X -120mm Y - 250mm Z - 250mm |

| Stal Torque X, Y & Z: | 8Nm |

| Rapid Speed: | 50 m/min max. (197 ft / min) |

| Axis Construction: | Ball Screw |

| Capability: | Horizontal Drilling Horizontal Milling Horizontal Boring |

| Integrated Spindle Motors: | Water Cooled Power @ 40%: 36 kW Torque @ 3,500 /12,000 RPM 98 / 29 Nm |

| Spindle Motor Interface: | HSK- E40 or E32 |

| Spindle Performance: | Standard Spindle RPM: 42,000 max Option 1 Spindle RPM: 20,000 max Option 2 Spindle RPM: 60,000 max |

| Optional Turning Module | |

| Size of cutting tool holder: | ¼” tool shanks ½” boring/Drilling holder |

| Capability: | Vertical Drilling Vertical Boring Vertical/Horizontal Turning |

| Tooling: | Up to 12 Turning or Drilling tools |

| Optional Mill/Turn Module | |

| Size of cutting tool holder: | ¼” tool shanks ½” boring/Drilling holder |

| Capability: | Vertical Drilling Vertical Boring Vertical/Horizontal Turning |

| Tooling: | 1 Fixed and 12 Turning or Drilling tools |

Saint Louis, Missouri

Saint Louis, Missouri