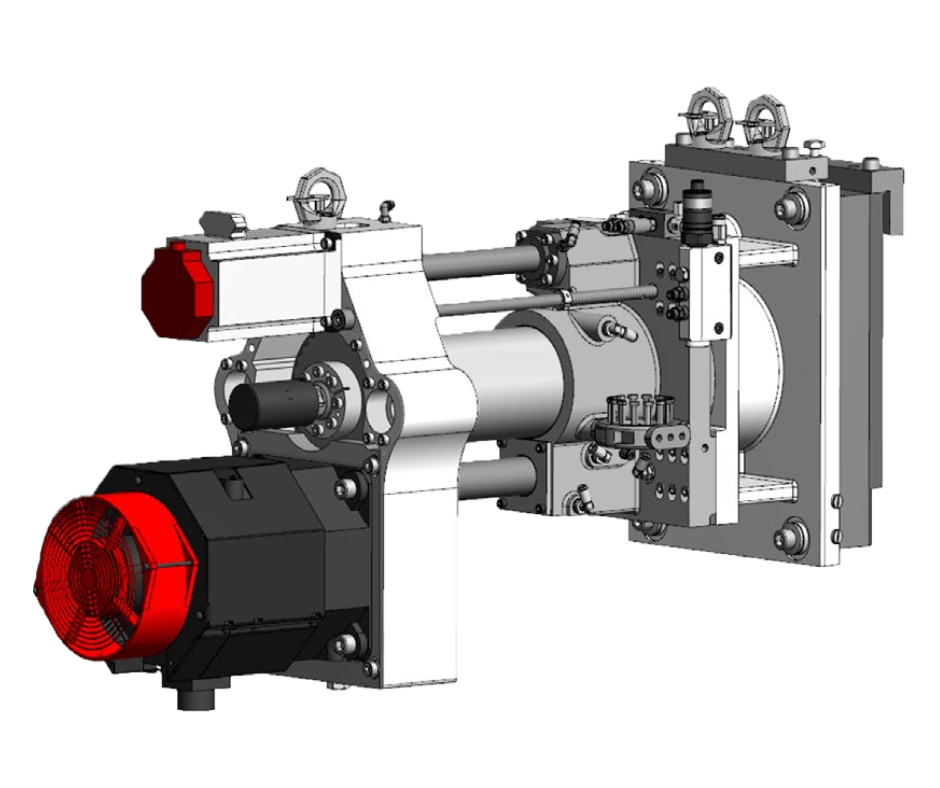

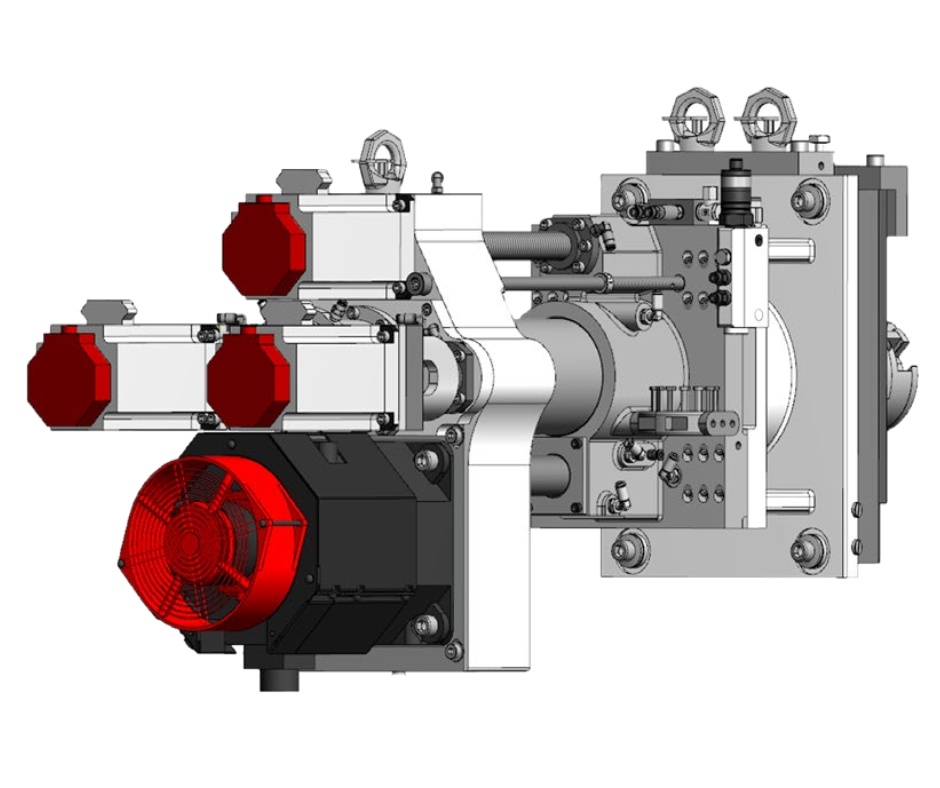

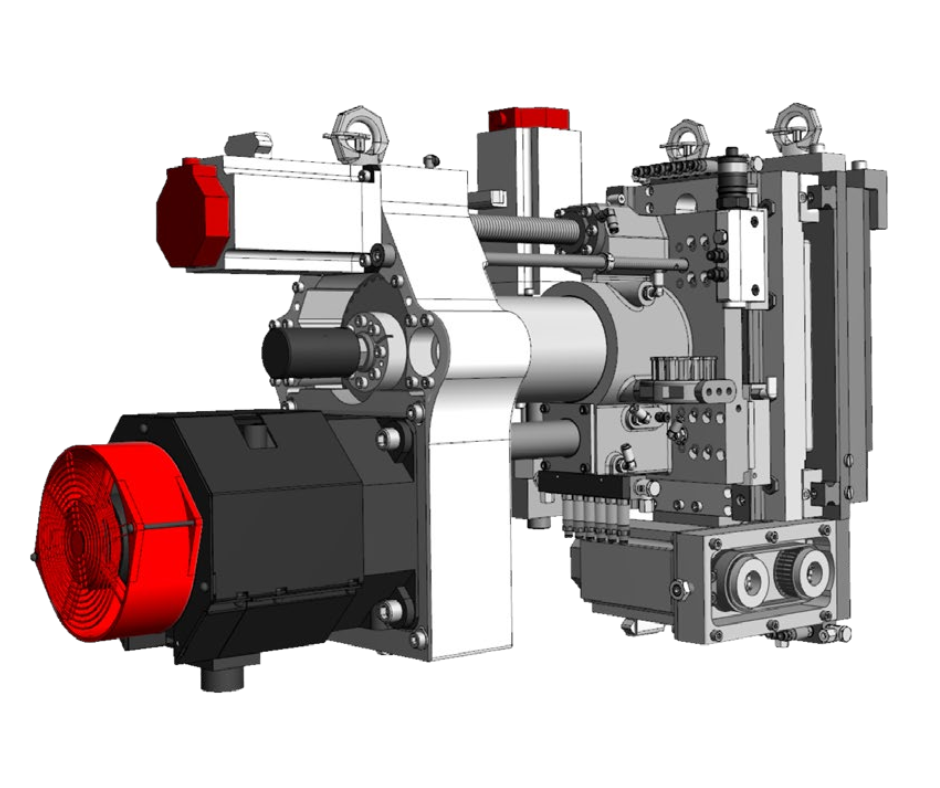

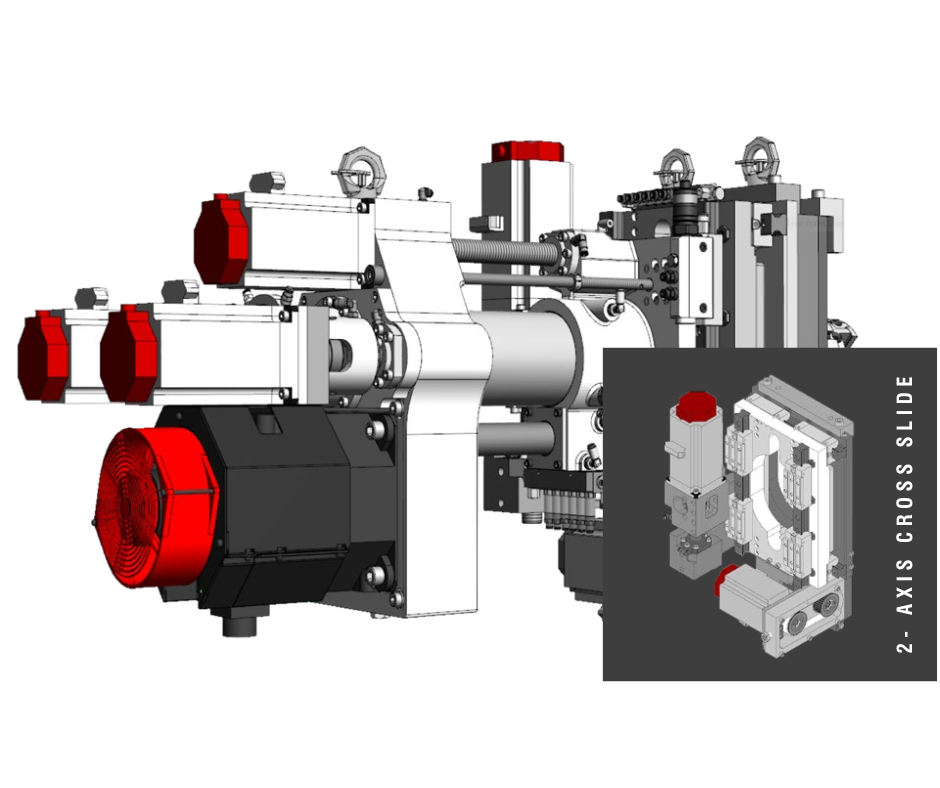

The Hydromat Force CNC Rotary Transfer Machine line of rotary transfer machines can be equipped with collets or chucks for precision metal cutting. This exceptional design is a modular system consisting of horizontal and vertical toolspindles mounted around a precision cast base.

This state-of-theart machine is a ballscrew electromechanical system that offers modularity with options for 1 through 4 axis configurations: providing drilling, tapping, threading, thread milling, single point threading, profiling, and milling capabilities.

All machines use the FANUC 30i-B as a controller option. A control known, used, and trusted industry-wide by many best-in-class machine manufacturers. FORCE CNC machines utilize 12 or 16 horizontal machining stations and have the available capacity of six vertical tool spindles on a 12-station machine and eight vertical tool spindles on a 16-station machine.

FORCE CNC Series Features

- Fully Electromechanical Machine with Ballscrew Drive Technology and Direct Drives

- Standard Machine Equipped Force 50/150 Tool Spindle Units Available in 1, 2, 3, & 4 Axis Configurations.

- Machining Capabilities: Drilling, Tapping, Threading, Thread Milling, Single Point Threading, Profiling, and Milling Capabilities

- Utilizes up to 12 or 16 Horizontal Machining Stations and 6 or 8 Vertical Machining Stations

- Maximum Spindle Speed: Mill / Drill Units 8,500 RPM and Lathe Turning 5000 RPM

- Maximum Stock Size that Ranges up to 1.75 Inch Round, 1.5 Inch Hex, 1.25 Inch Square, and a Part Length to 6 Inches

- Designed, Engineered, and Assembled by Hydromat OEM Experts and FANUC Authorized Integrator

Saint Louis, Missouri - EE. UU.

Saint Louis, Missouri - EE. UU.

-eurdkg.png)