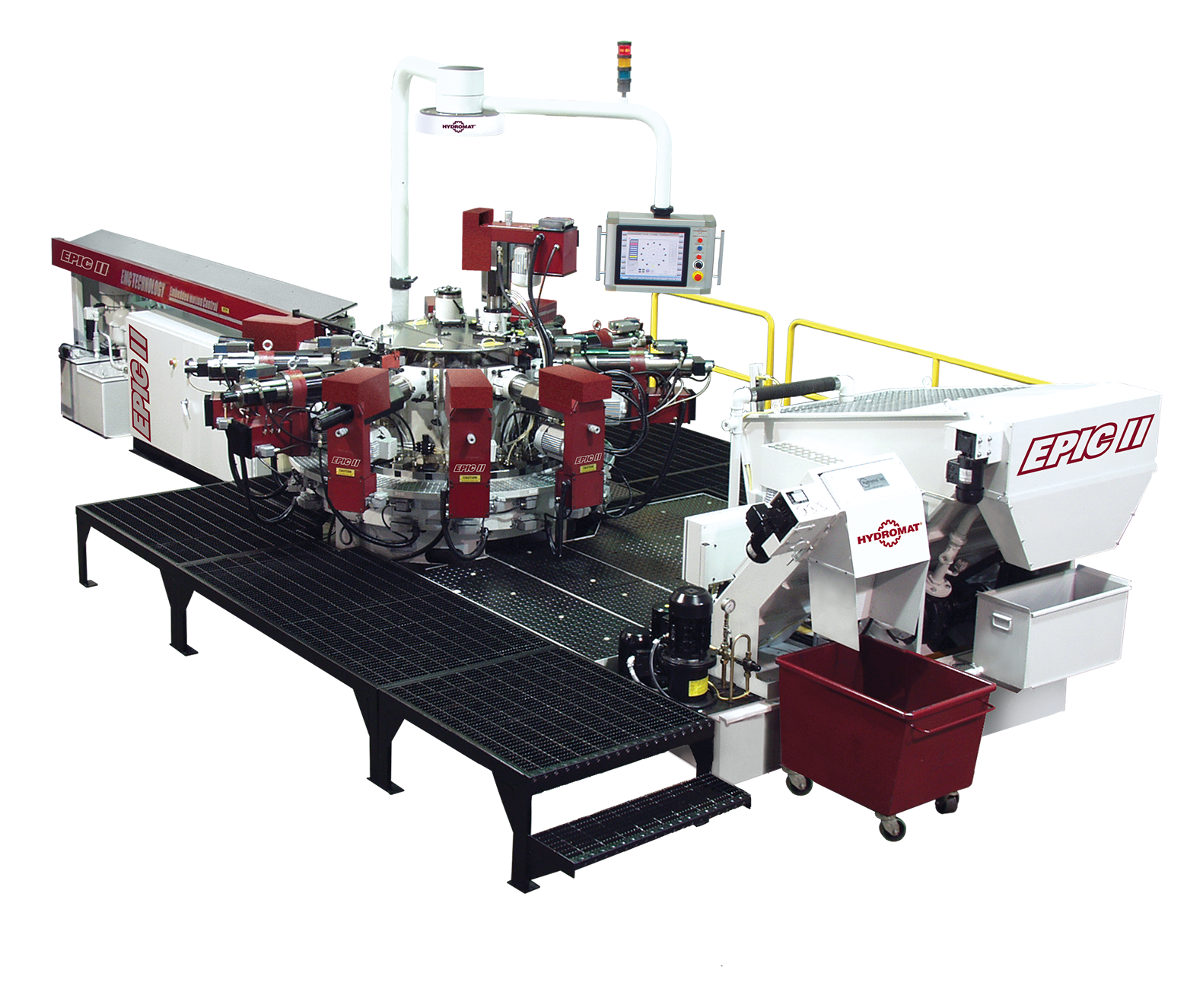

Product Image

This new iteration of the EPIC platform boasts advancements such as enhanced operations, production reporting, down time analysis, trouble shooting, and preventative maintenance interval scheduling. These features, among others, will yield improved part set-ups, changeovers, process tooling development, and integrated tool monitoring. An upgraded servo control features absolute positioning, and a more efficient architecture that reduces failure points.

The EPIC II is a rotary transfer solution specifically made for advanced production solutions in the future. The wide variety of EPIC II rotary transfer machines offered by Hydromat give production machining professionals the right tool for the right job. The Hydromat system is the solution for the elimination of secondary operations by producing parts complete from bar stock, castings, forgings or cold formed blanks. The Hydromat machining platform reduces work in progress with additional cost reduction realized due to extremely short remnants that translate to significant material saving. Increased productivity is partially due to modular toolspindle system with quick-change presettable tool heads for easy changeovers.

Características

- Up to 12 horizontal & 6 vertical machining stations

- Handles up to 25mm diameters in square, round, or hex bar stock

- Several different unit sizes available

- Multiple Loading and Chip Systems options

- Coolant fed or Flange Quill operations

- Every machine sold is individually engineered for optimal cycle time

- Full CNC programming capabilities

- Supports lean manufacturing principals

- Quick, easy, changeovers - typically 1-3 hours

- Competitive manufacturing for small, medium, and large production

- Integrated modem connections provide fast problem solving

- Improved Accuracy with Absolute Positioning Which Eliminates Need for Unit Home Prox

- Replacement Servo Valves Can Be Locally Configured and Programmed On the Machine And Does Not Require Hydromat Assistance

- Expanded Canned Cycle Selections to Generate Programs Faster and Easier

- Enhanced Operation, Trouble Shooting, and PM Intervals

- Standard CNC Controls for Improved Part Set-Up, Change-Overs, and Process-Tooling Development

- Integrated Tool Monitoring

EPIC II Control Benefits

- No PMAC EPIC Boxes

- Bosch CNC/PLC Common Control

- Direct Access for Valves, Programming, & Feedback

- Standardized Common Servo Valve

- Reduced Wiring and Machine Plugs

- Efficient Architecture with Reduced Failure Points

Opciones adicionales de configuración de la máquina

- Loading Options

- Chip Systems

- Units

- Coolant Chiller

- Tooling

Ventajas de Hydromat sobre el mecanizado convencional

| Max Stock Size | ||||||||

|---|---|---|---|---|---|---|---|---|

| Rnd | Hex | Sq | Hor. Station | Vert. Station | Index Time | Weight LBS | Machine Power | Size Unit Options |

| 1" | 7/8" | 3/4" | 12 | 6 | 0.500 sec | 10,000 | 60HP (Avg) | EPIC 26/80 EPIC 36/100 EPIC 46/120 EPIC 50/100 |

Saint Louis, Missouri - EE. UU.

Saint Louis, Missouri - EE. UU.